Industry: 3C Applications

Application Scenario: Traditional solutions, such as basic thermal interface materials and heat dissipation designs utilizing aluminum alloy or stainless steel frames, have proven inadequate. While these conventional methods can manage short bursts of "peak performance" from the A-series chips, they struggle to meet the demands of sustained high-load AI tasks.

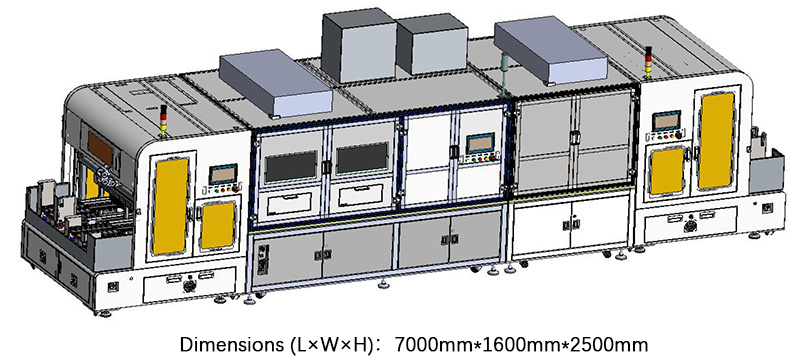

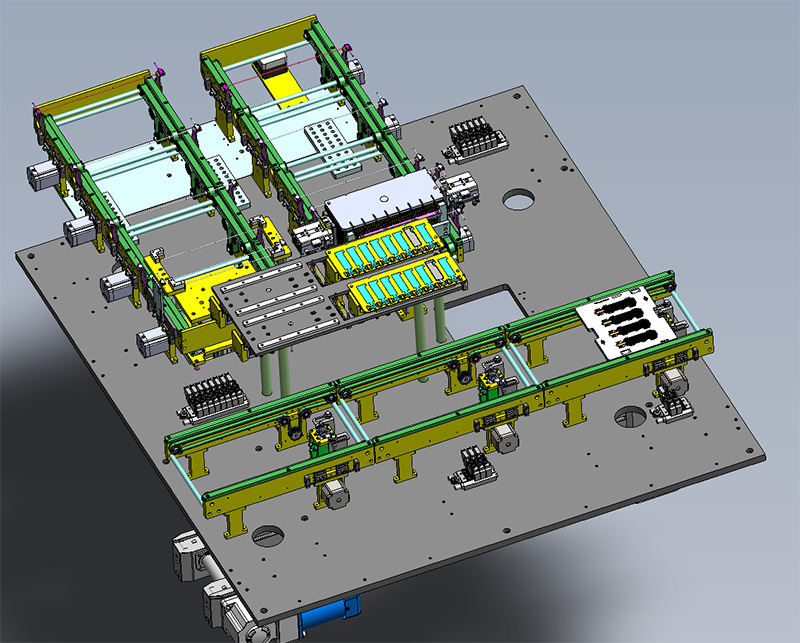

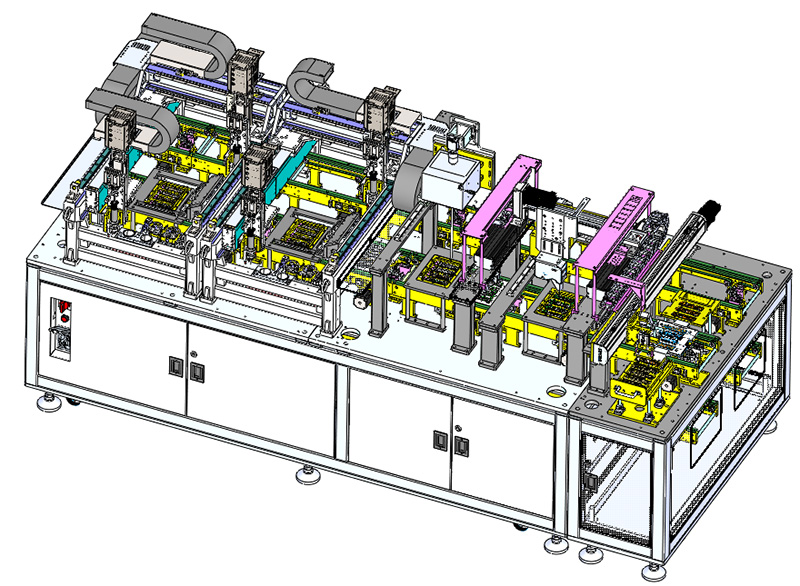

Equipment Role & Overall Objective: This system is designed for the automated assembly of vapor chambers (VCs). It aims to eliminate manual operations, increase process efficiency, and reduce variability caused by human factors.

Core Functions:

1,M5

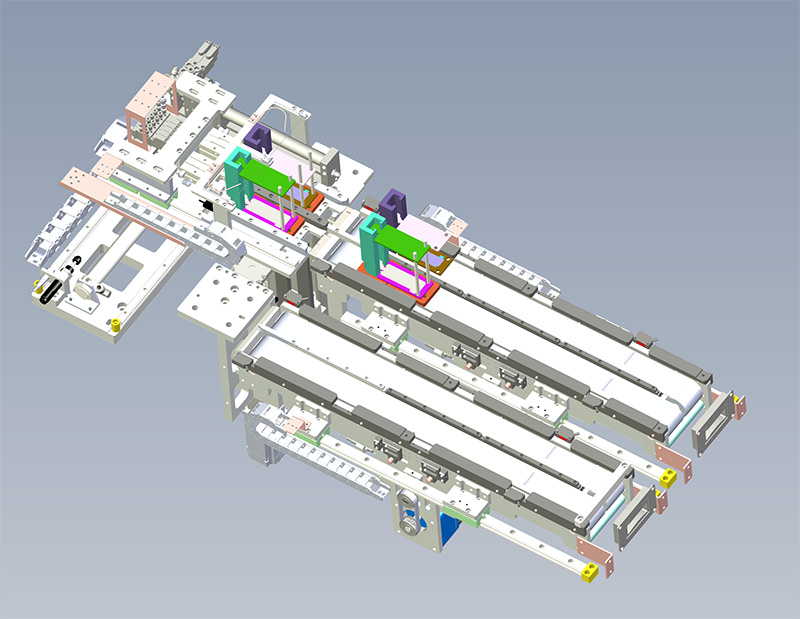

1.1Dual-Magazine Feeding:

It utilizes dual feeding stations to reduce changeover frequency and allows for pre-loading to minimize equipment idle time.

1.2 The single station integrates feeding, stamping, and AOI inspection for multifunctional consolidation.

|

Stamping |

AOI |

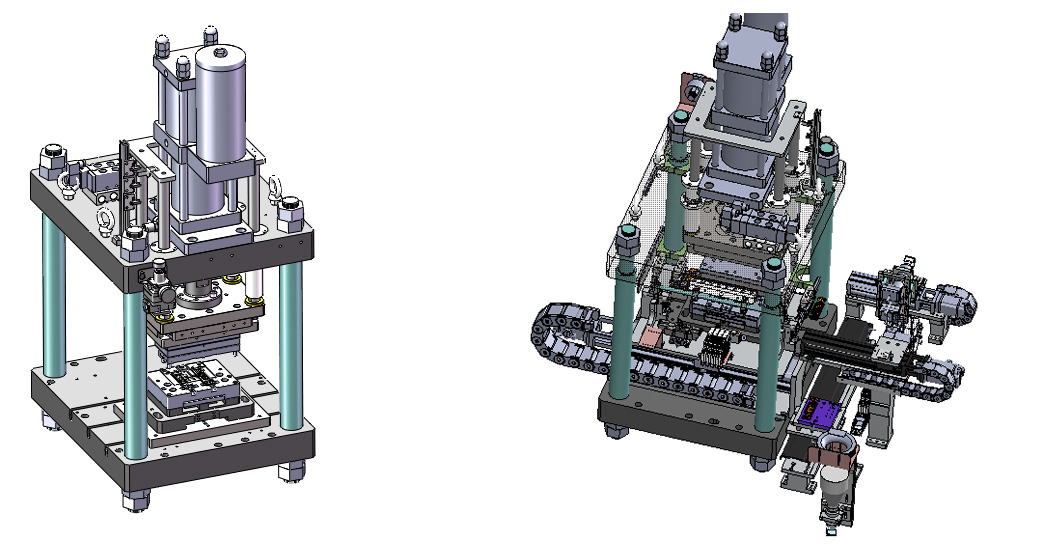

2、M6

2.1 Tray separating mechanism:Visual-guided graphite splitting is adopted, with complex electrical control logic.

3、Dispensing

This station features a dual-dispensing setup to meet the target UPH. It synchronously integrates 2D and 3D cameras to monitor adhesive bead parameters in real time, ensuring high yield rates.

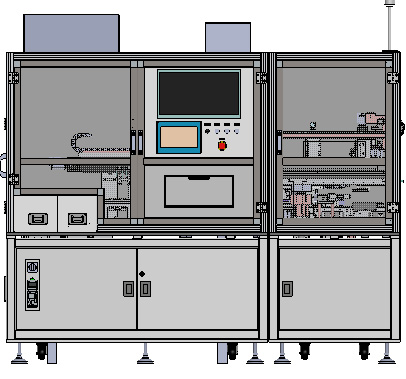

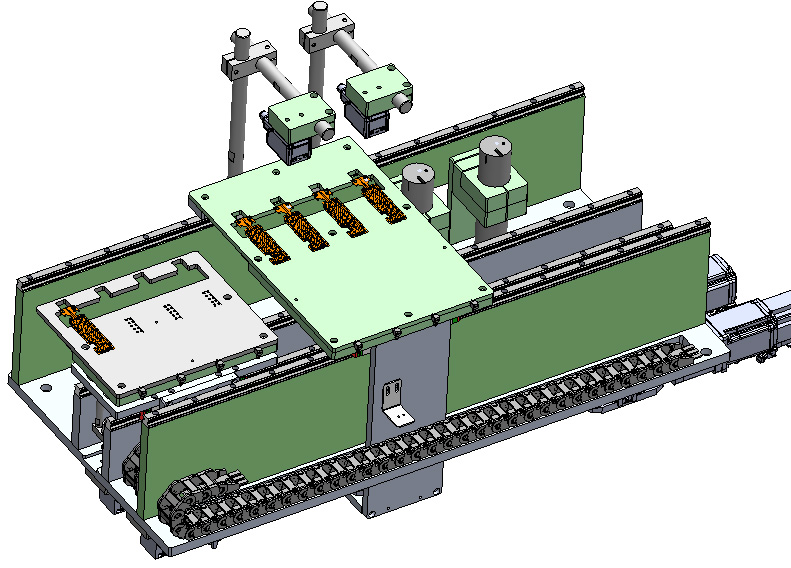

4、Code Conversion and Header Cutting Equipment:

4.1 Barcode Scanning Platform

It utilizes alternating top and bottom platforms for staggered barcode scanning, saving space.

UPH Yield & Efficiency:

1,Molding Line Overall Performance:

Design UPH: 750 | Achievable UPH: 820

Target Yield: 95% | Achievable Yield: 99.98%

Target Efficiency: 85% | Achievable Efficiency: 93%

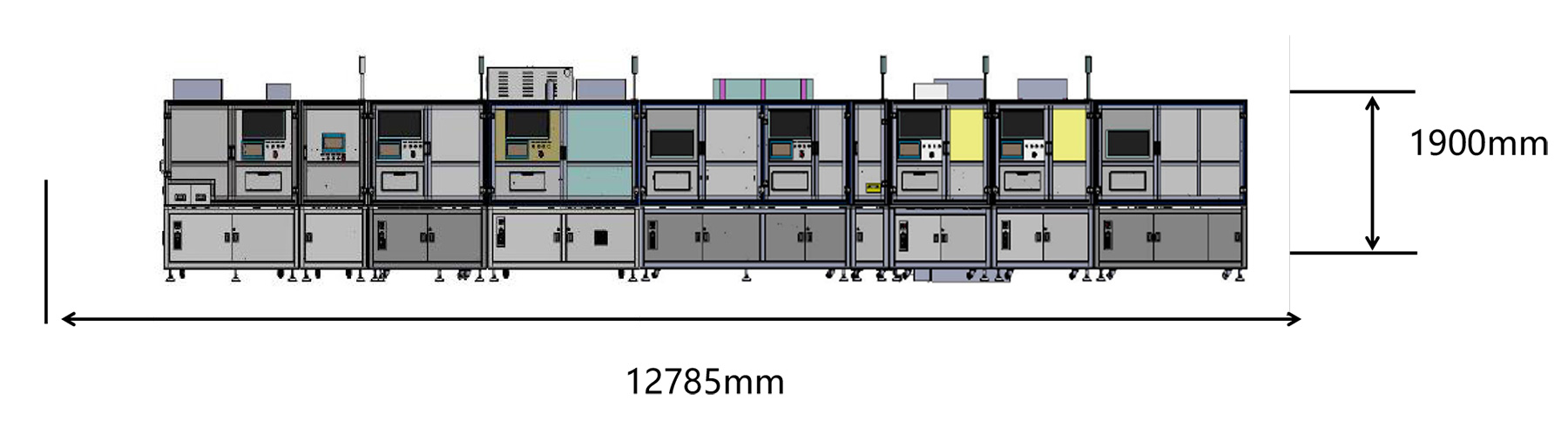

2,Code Conversion Line Overall Performance:

Design UPH: 1200 | Achievable UPH: 1300

Target Yield: 95% | Achievable Yield: 99.98%

Target Efficiency: 85% | Achievable Efficiency: 93%

Physical Photos of the Equipment:

Molding Line:

Code Conversion Line: