Industry: 3C Electronics / Computer & Server Manufacturing

Application Scenario: This automated line is designed for the precision assembly of CPU heat sinks and PCB boards in devices such as servers and high-end desktop computers. Specific processes include cleaning the copper base of the heat sink, applying Phase Change Material (PCM), quality inspection, and the final precise assembly and fastening with the PCB.

Customer Requirements Background:

1.Enhance the level of automation: Transition the current labor-intensive processes of heat sink handling and assembly to automated operations, reducing manual intervention and ensuring consistency.

2.Achieve high-precision operations: Implement stringent accuracy requirements for key processes such as cleaning, PCM application, film removal, and assembly to ensure product quality and thermal performance.

3.Ensure Controllable Quality: Requires 100% online inspection of PCM application position, coverage, blistering, and final assembly status to prevent defective products from leaving the production line.

4.Address Existing Process Challenges: Specifically resolve issues such as heat sink clamping and positioning, incoming tolerance of PCB studs, post-assembly floating height, and film removal difficulties caused by static electricity.

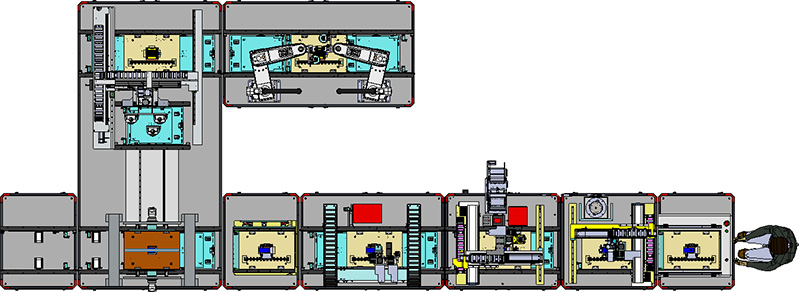

Equipment Function & Overall Objective: This system is designed for the automated cleaning of heat sinks, PCM application, visual inspection, flip assembly, and screw fastening. By integrating precision mechanical design, multi-axis robots, top/bottom vision alignment, 2D/3D inspection, and sensor feedback technology, it establishes a high-precision, high-yield automated production line to achieve accurate and reliable assembly of heat sinks and PCBs.

Core Functions: Visual positioning, 2D/3D vision inspection for coverage, bubbles, and blisters, laser height measurement.

1.Automated Material Flow:

· Heat Sink: Manual loading. Carriers automatically circulate within the equipment.

· PCB: Carriers flow in from the previous station via conveyor and out to the next station.

· NG Product Handling: NG heat sinks detected are automatically returned with the carrier to the loading position for manual handling.

2. Precision Cleaning & Application:

· Copper Base Cleaning: Utilizes non-woven fabric rolling + IPA solvent spray, equipped with pressure sensors and flow meters for controlled cleaning force and solvent usage.

· PCM Application: Roll-fed supply. Uses top/bottom vision alignment and a 4-axis robot for precise application onto the heat sink copper base area.

3. Full-Process Quality Inspection:

· PCM Application AOI: 2D vision inspects application position and coverage; 3D line scan inspects for blisters and flatness.

· Incoming Pre-inspection: At the lift station, a CCD checks PCB stud positions to proactively prevent assembly and fastening issues.

· Post-Assembly Inspection: A laser displacement sensor checks for heat sink floating height after assembly.

4. High-Precision Assembly & Fastening:

· Heat Sink Assembly: A 180° carrier flipping mechanism transfers the heat sink from Carrier A to Carrier B. Precision assembly is achieved using top/bottom vision and a buffered gripper.

· Screw Fastening: Employs dual 4-axis robots with electric screwdrivers. A multi-stage pre-fastening strategy ensures smooth screw entry, assisted by CCD positioning.

Technical Highlights:

1.Tolerance Absorption & Precision Alignment Design:

· Key stations incorporate linear slides with spring damping mechanisms to absorb product tolerances.

· Extensive use of top/bottom vision alignment systems ensures precision in PCM application and heat sink assembly.

2.Targeted Process Innovation:

The film removal station utilizes vortex tube cooling to prevent adhesion and ionizing air bars for static elimination, addressing common industry challenges.

Proposed design enhancements for the assembly station, including adding floating support blocks for the PCB carrier and elongated locating pins for the heat sink, fundamentally improve assembly fit and contact.

3.Modular & Flexible Material Handling Design: Features an internal circulation system for heat sink carriers and a linear flow for PCB carriers. The compact footprint (7660*2000mm) supports quick changeover and accommodates material flow requirements for different products.

4.Data-Driven Process Monitoring: Key process parameters (e.g., wiping force, cleaning solution volume, application pressure, screw torque) are monitored via sensors, establishing a foundation for data traceability and process optimization.

Performance Parameters: UPH: 50 / Yield: 99.5% / Uptime: 85%

Equipment Images: