Industry: Electronics 3C Industry

Application Scenario: Indoor, automated equipment operation

Customer Requirements Background: Increase production capacity and reduce labor costs

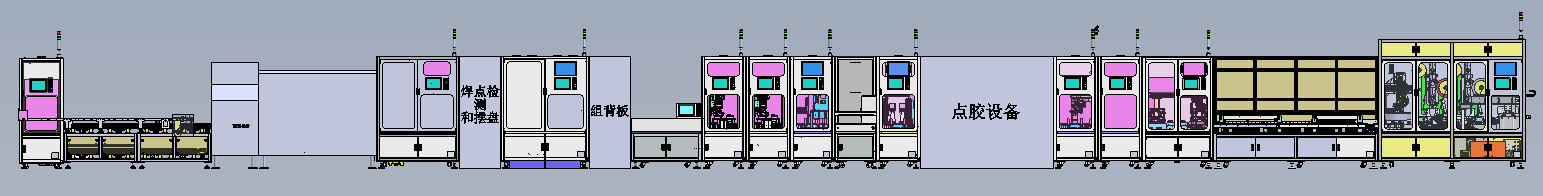

Equipment Role & Overall Objective: Designed for automated power supply assembly, combining manual assistance with equipment automation for product assembly.

Core Functions: Automated loading/unloading, automated dispensing, equipment inspection, data tracking, automated ultrasonic welding.

Technical Highlights:

1.Highly Integrated Automation: Utilizes robots, modules, and conveyor lines for collaborative operation, covering insertion, welding, fastening, assembly, and inspection processes to minimize manual intervention and improve assembly efficiency.

2.Flexible Production Adaptability: Modular design enables quick changeover (≤30 minutes) for different power supply models and wattages, supporting multi-variant, small-batch production needs and reducing line modification costs.

3.Intelligent Control & Energy Efficiency: Integrated with MES for real-time monitoring of production capacity, yield, and equipment status. Equipped with energy-saving drive motors and smart power-off design to reduce energy consumption.

Performance Parameters: UPH ≥ 1200, Yield ≥ 99%

Equipment Photos: