Industry: Electronics Industry

Application Scenario: Assembly line for high-performance server thermal modules.

Customer Requirements Background:

· Increase production capacity.

· Reduce defect rates caused by manual assembly.

· Utilize existing 90W equipment and, based on requirements, fabricate new or retrofit equipment to ensure compatibility with 190W/300W products.

Equipment Role & Overall Objective:

· Role: A human-in-the-loop automated assembly line for lean production of high-performance server thermal modules (compatible with 90W/190W/300W models).

· Overall Objective: To achieve compatible production of 90W/190W/300W models, improve production efficiency (UPH), reduce defects caused by manual intervention, and ensure product quality.

Core Functions:

· Automatic Loading/Unloading: Implements automatic material handling to reduce operator workload.

· Vision Positioning/Inspection: Widely deployed across multiple stations for solder paste inspection (SPI) and product inspection.

· Data Traceability: Monitors and records production process data, establishing a foundation for product and process traceability.

· Carrier Flow & Management: Features dedicated sub-line and main-line carriers with both automated and manual transfer mechanisms.

Technical Highlights:

· Modular Design: Facilitates equipment updates, maintenance, retrofits, and upgrades.

· Model Compatibility: Capable of processing 90W, 190W, and 300W products, enhancing equipment versatility.

· Integration of Existing & New Equipment: Maximizes utilization of current assets while fabricating new or modified equipment as needed to optimize cost-effectiveness.

· Vision Inspection Solution: Employs 2D/3D vision at inspection stations to precisely control solder paste volume.

Performance Parameters:

Output: UPH 200

Yield: Assembly yield improved from 95% to over 98.8%

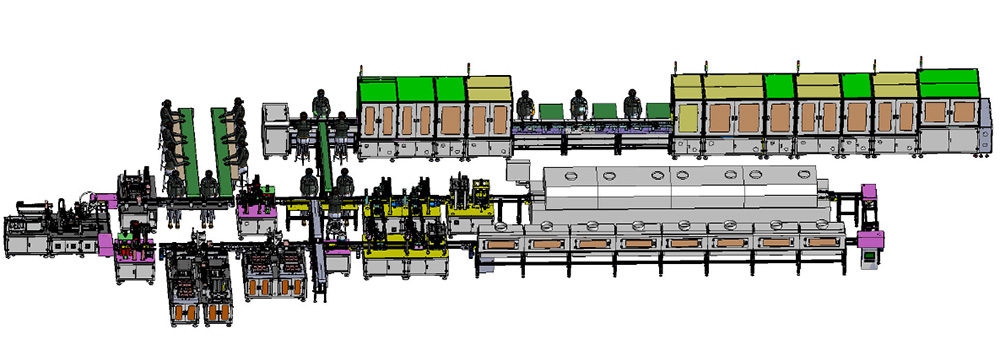

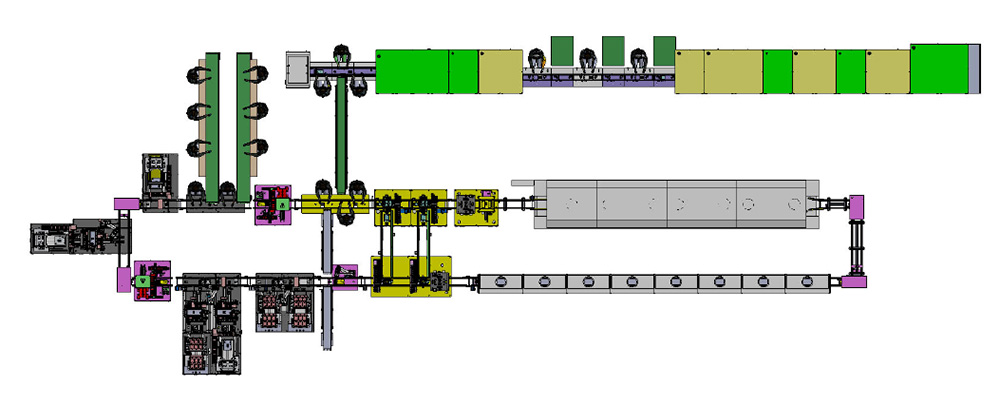

Equipment Photos: