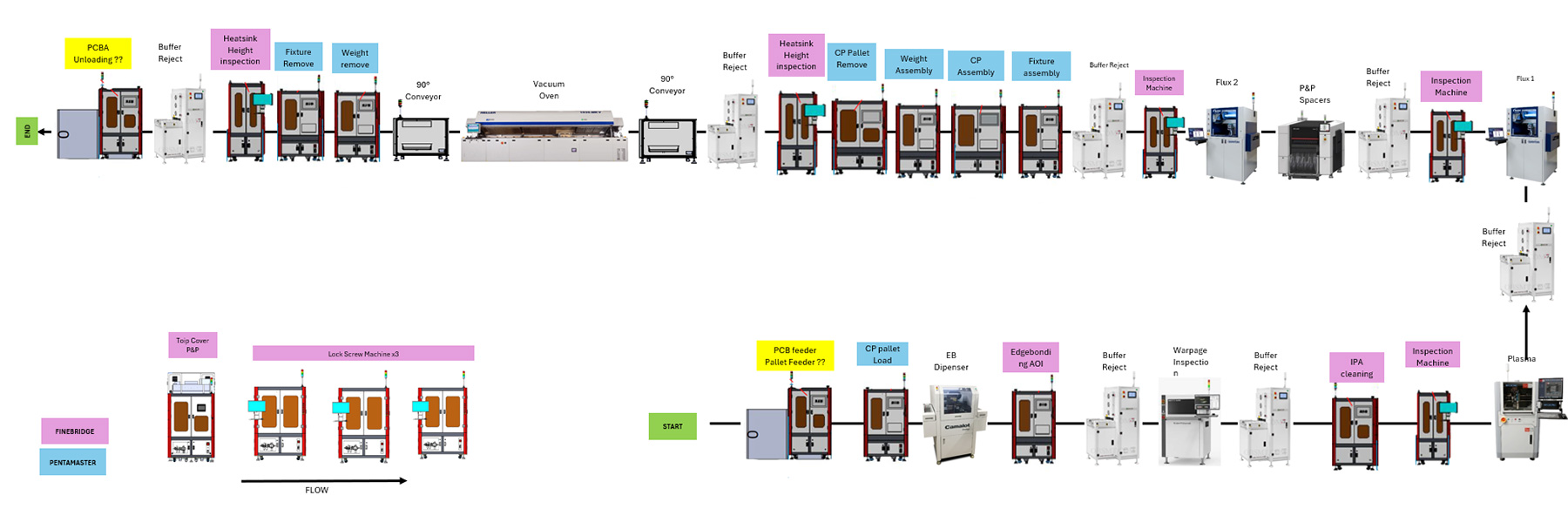

Industry: 3C Electronics / Computer and Server Manufacturing Industry

Application Scenario: Assembly, cleaning, and inspection in the server heat dissipation industry

Equipment Function and Overall Goal: Construct an automated production line integrating height inspection, appearance inspection, cleaning, screw locking, and glue application inspection. By leveraging high-precision vision systems, robotic technology, and precision motion control, it realizes high-quality and high-efficiency automated production and inspection of electronic components.

Core Functions:

1. High-Precision 3D Vision Inspection

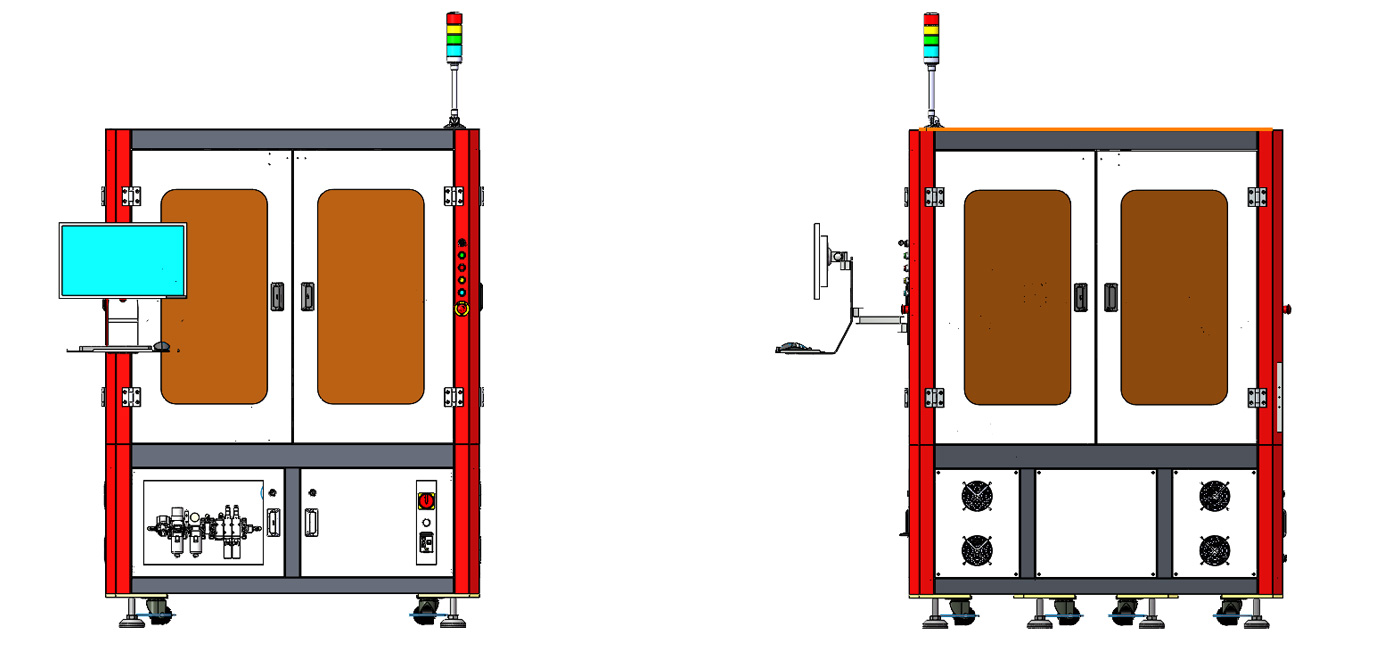

· Heat Sink Height and Flatness Inspection: Adopts 3D line-scan laser with an accuracy of up to ±1.5μm.

· Component Appearance Inspection: Detects the presence/absence of O-rings and silicone pads, as well as foreign objects.

· Glue Application Quality AOI Inspection: Detects defects such as the presence/absence of glue paths, glue breaks, and irregular glue thickness.

2. Precision Cleaning and Assembly

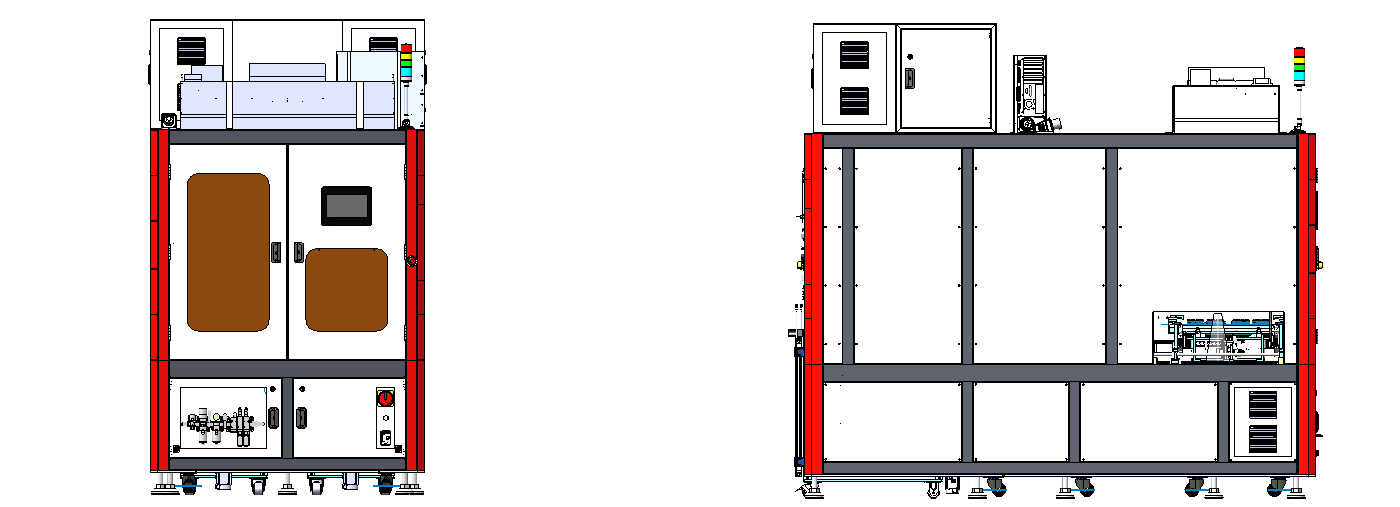

· IPA Cleaning: Automatically cleans the surfaces of CPU sockets and heat sinks with isopropyl alcohol to ensure no dust or oil residues.

· Automatic Upper Cover Assembly: Features precision press-fitting to ensure components are assembled without damage and in place.

3. Intelligent Tightening and Data Traceability

· Multi-Axis Screw Locking: Two electric screwdrivers work synchronously, with real-time monitoring of torque and angle to prevent missing screws and thread stripping.

· Whole-Process Data Recording: All process parameters (cleaning pressure, screw torque, inspection results) are recorded and traceable to the MES system.

Technical Highlights:

· Highly Modular and Flexible Design: The entire line consists of multiple independent standardized modules (e.g., cleaning, locking, inspection modules). It can be flexibly configured, upgraded, and maintained according to process requirements.

· Hybrid, Multi-Stage In-Line Quality Inspection System: Integrates multiple inspection technologies such as 2D vision, 3D line scanning, and collaborative robot vision. Quality control checkpoints are set at key nodes in the production process to prevent defective products from flowing into the next workstation.

· High-Rigidity and High-Precision Motion Platform: Widely uses marble platforms, linear motors, and high-precision lead screw modules, providing a solid foundation for high-speed and high-precision measurement and assembly operations.

· Advanced Closed-Loop Process Control: Realizes closed-loop monitoring of torque and pressure at the locking workstation; achieves closed-loop control of cleaning fluid flow at the cleaning workstation, ensuring high consistency and reliability of core processes.

· Dual-Task Parallel Processing: The locking gantry adopts a dual-X-axis and dual-Y-axis dual-drive design, enabling simultaneous locking of two screws. Compared with the single-axis design, it significantly shortens the workstation cycle time (CT).

Performance Parameters:

UPH (Units Per Hour) 80 Yield Rate:99.5% Operation Rate93%

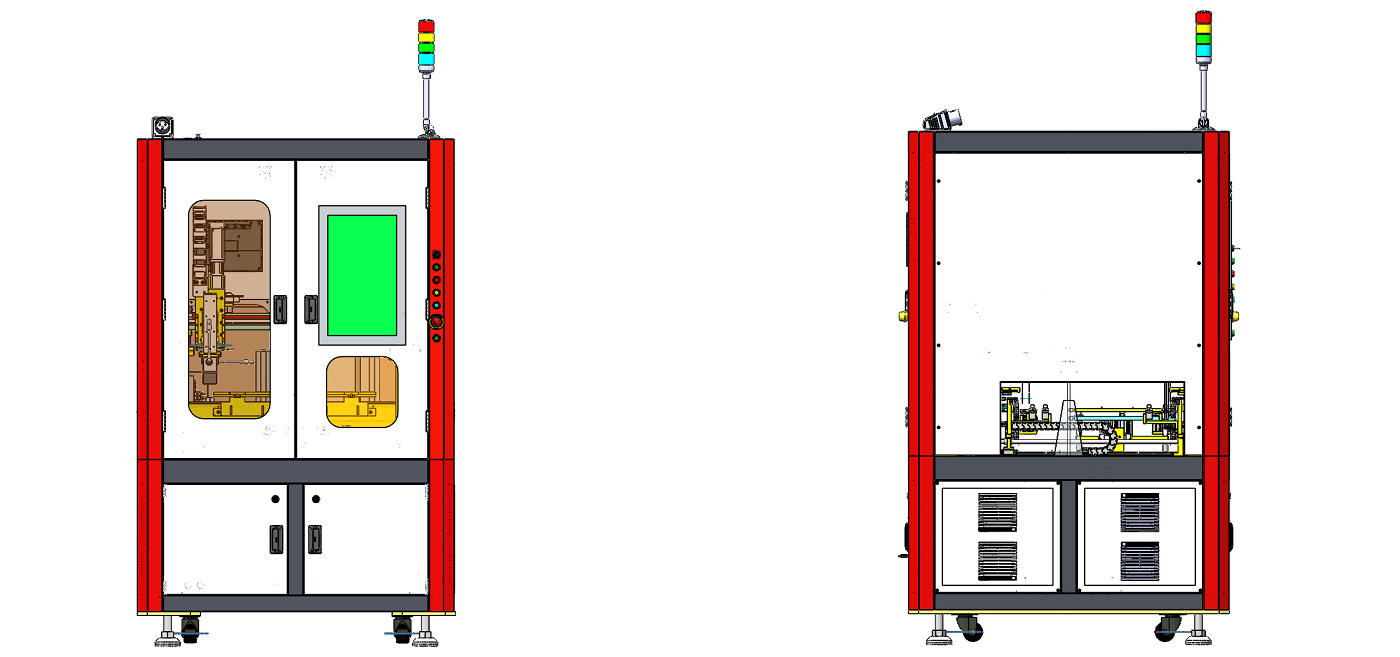

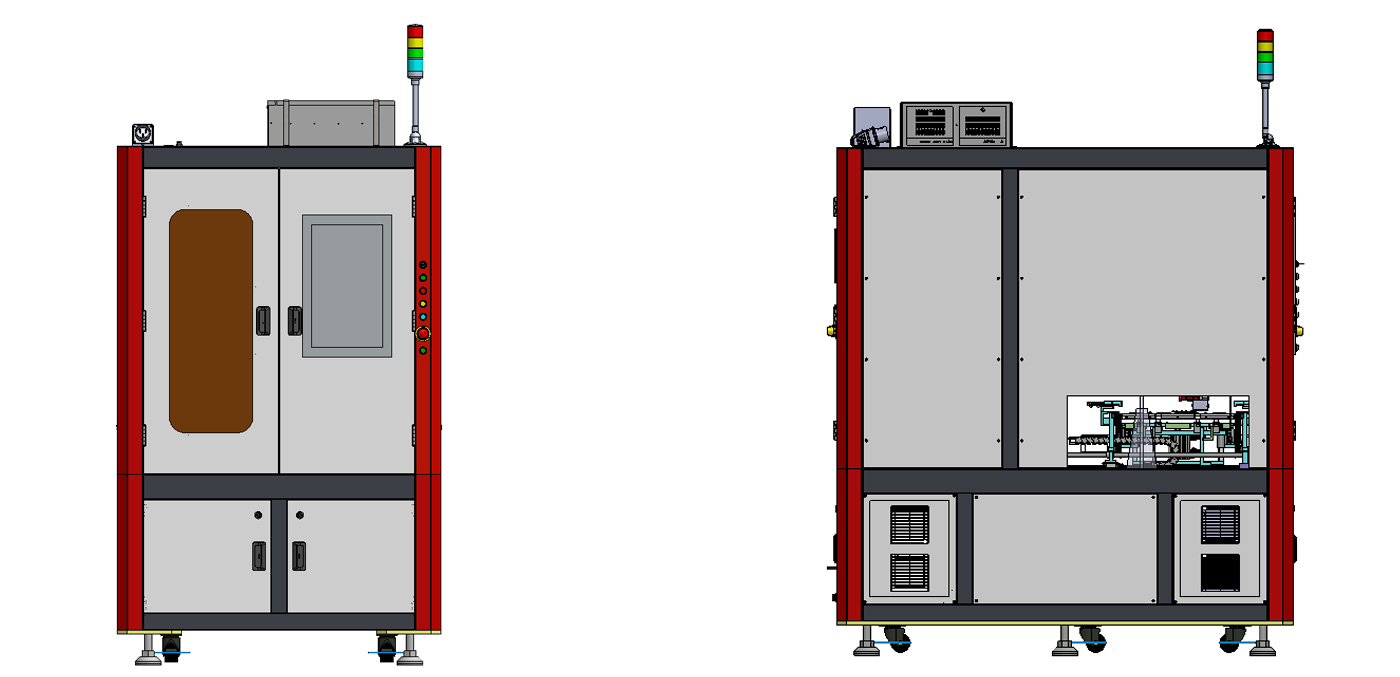

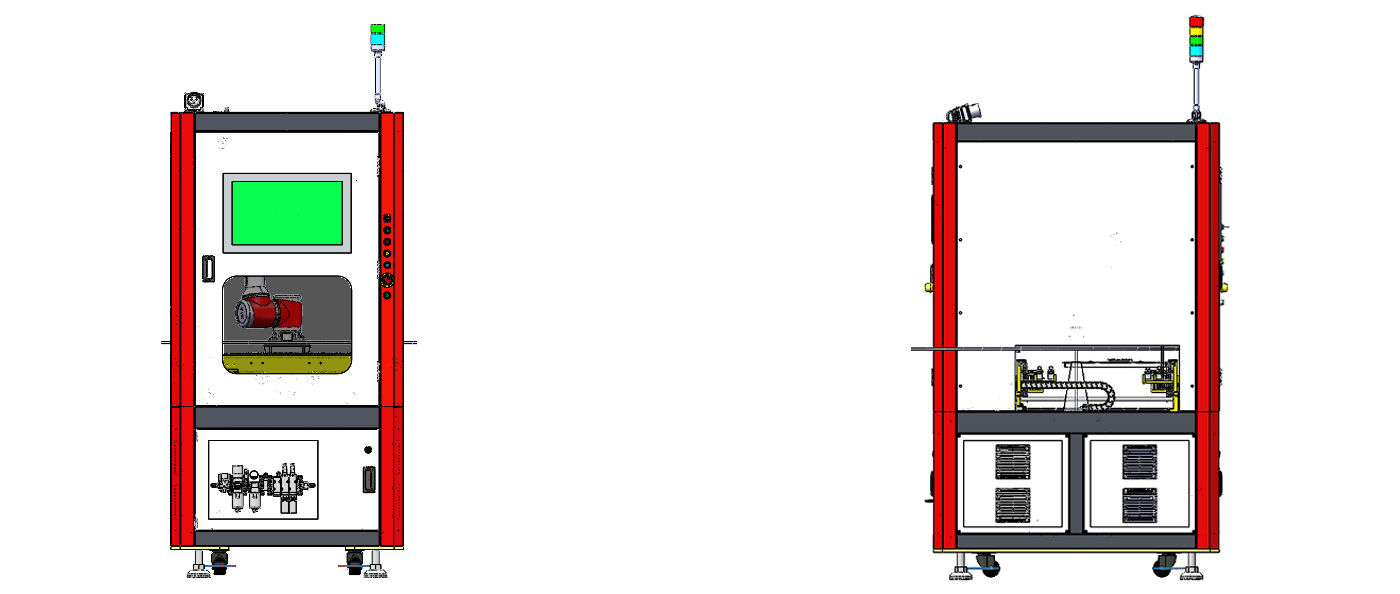

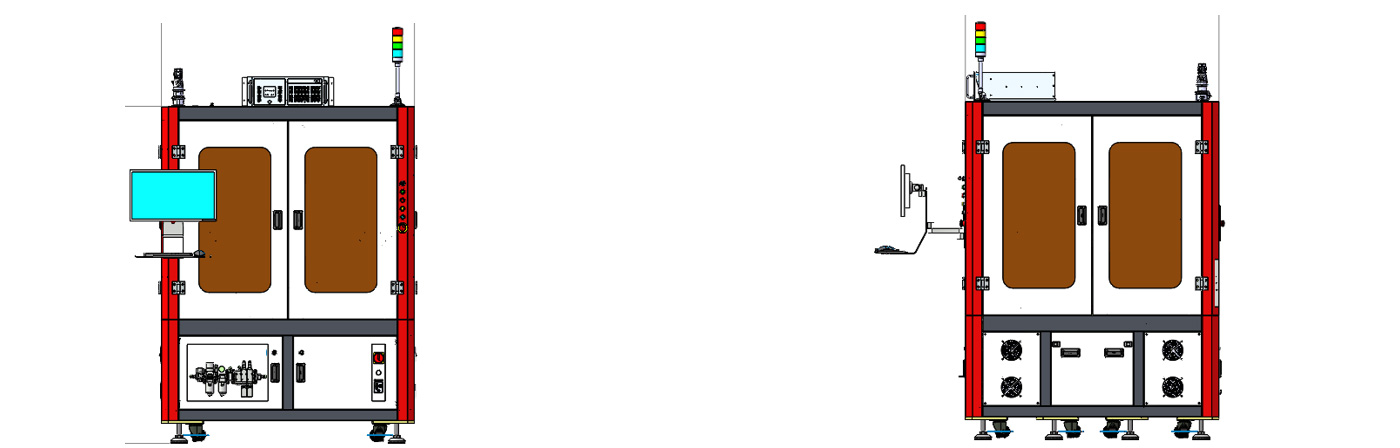

Equipment Images:

Cover Assembly

Screw Machine

IPA Cleaner

2D Inspection

Height Inspection

Edgebonding Inspection